EarthWolf Farms’ Journey

Written by Brishna Kamal

2022-01-27

Whistler Therapeutics d.b.a. EarthWolf Farms is a locally owned and family operated company focused on creating cannabis products from organically grown cannabis, testing it for quality specifications and bringing it to market. Founded in Whistler, BC, we have operations in Vancouver, Whistler and Lillooet and offer cannabis consulting services worldwide. We, as founders have worked for many years in the legal medical cannabis industry before starting Whistler Therapeutics, with the goal of creating clinically tested medicine from organic cannabis grown outdoors. We believe that the production of any medicine should not harm our environment and are committed to using regenerative agriculture practices and solvent-free processing to create medicine that benefits both patients and the planet.

When the government of Canada introduced legislation to make cannabis legal for adult use in October 2018, they also made outdoor cannabis production legal. Due to its unique climate, Lillooet and the surrounding area are very well suited to growing outdoor cannabis. Outdoor cannabis production in most parts of Canada is limited by sunshine, temperature, fall rains and humidity. Most of British Columbia experiences heavy rainfall in autumn, causing significant crop loss due to mold for many varieties of cannabis grown outdoors. Outdoor growing in these regions is limited to certain cultivars of cannabis that mature quickly and/or are mold-resistant, but with limited commercial value. Many high-value cannabis varieties do not mature quickly enough in the wetter climates of BC and will be lost to mold before the flowers are commercially viable. The semi-arid climate of the Lillooet-Lytton area is the driest in all of Canada, and thus reduces the risk of crop loss due to mold. High-value cannabis varieties which cannot be produced in Pemberton, the Lower mainland or the Kootenays will come to maturity in Lillooet with minimal crop loss. Furthermore, Lillooet averaged 2,960 hours of sun in 2017, 2018 and 2019, making it one of the sunniest and hottest places in Canada, Ideal for cannabis agriculture. There is no other region in Canada that has as much potential for growing cannabis as this area, and for that reason, we chose to launch our outdoor operations in the Lillooet area.

In 2017, we started exploring the Lillooet area as part of our recreational lifestyles, summiting local mountain peaks, and learning more about its history while eating sun-kissed peaches and apricots growing wild in the Lillooet area. The drive from Whistler to Lillooet left us breathless in all seasons and we started looking for a farm property with the right zoning for cannabis cultivation as per District of Lillooet and Squamish SLRD Zoning By-Laws. In early 2019, we found a hop farm parcel (20 acres) for sale in East Lillooet that met requirements for cannabis cultivation (Agriculture zoned and previously used to be ALR) and we would be able to do the licensing ourselves with the federal government pursuant to the Cannabis Act. At this time, we had an idea and not much more but each other as founders. We went to raise capital from family and friends to finance our ideas into reality. We were lucky enough to convince family members to buy the parcel and leaseback to us. At this time, we also started looking into other rental buildings to process the cannabis biomass. April 20th 2019, was our first overnight camp-style stay at the farm property, and we cleared the farm where there were no hops currently sprouting. We thought we would be able to build something also on this parcel for processing of cannabis yet in early May 2019, the federal government changed licensing requirements requiring sites to be fully built before an application for licensing could be summited and introduced a new & revised set of class licenses, separating cultivation from processing from sales (previously one license class with activities added on with amendments to licenses). We had to pivot with this news as the capital we had raised would not support cultivation and processing to be implemented simultaneously. We decided to go ahead and build the infrastructure required to get a standard cultivation license with the funds we had raised and hoped we would be able to offset additional costs from loans from our other company, Whistler Technologies, which sells large-scale food and medical grade solventless extraction equipment. At the same time, we also decided to continue growing the hops and processing them as we would cannabis as a trial run of our abilities as farmers. Hops farms around & in Lillooet had to stop cultivating hops due to the processor having left town and we wanted to see if we could also market Whistler Technologies equipment in the organics hops industry, with demand for hop extracts continuing to increase with the increased number of small microbreweries.

Having made this decision to start with a standard cannabis cultivation license, we knew there were and still are logistical challenges of getting large amounts of cannabis processed (dried/cured or extracted) and to market. A bottleneck of drying and processing facilities means there is difficulty in getting large outdoor crops to market. Whistler Technologies has been designing equipment specifically to meet the needs of outdoor cannabis farmers to process large amounts of biomass that can be frozen directly after harvest. This technology allows for a lower-cost production of organic cannabis extracts to feed domestic or international markets. Skipping the drying step avoids a significant risk point for outdoor cultivation and avoids potential complaints from odours that often occur from drying facilities. Drying facilities, along with greenhouse operations, have problems with large amounts of cannabis odour escaping all at once. Outdoor growth and ice water processing do not create bursts of concentrated odour and have less detrimental effects on residents. We were on the lookout for a building to rent for processing quality solventless concentrates for the nascent cannabis industry. We needed something to process the harvested biomass from our first cycle of cannabis cultivation.

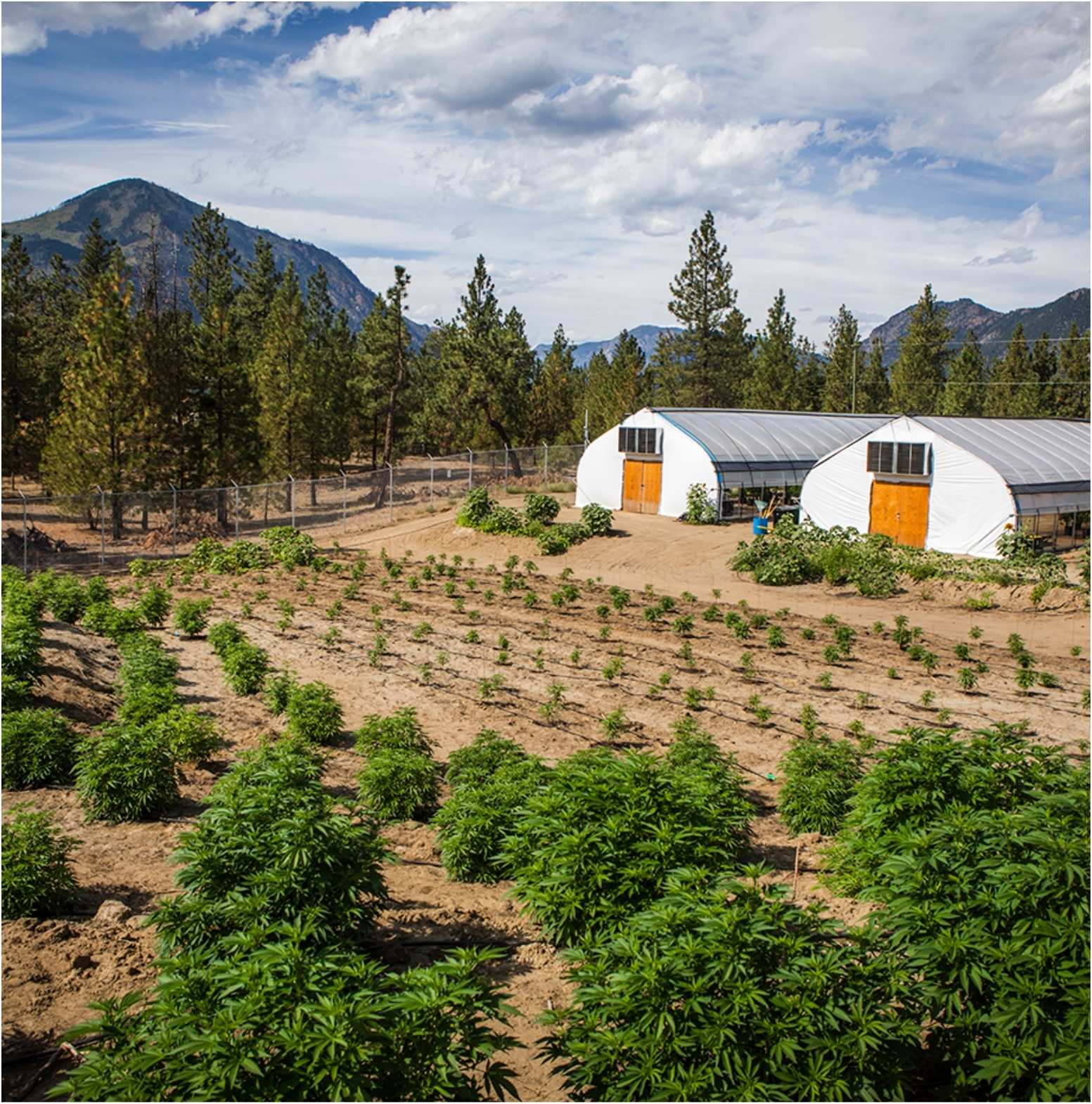

Earthwolf Farms, located at 1199 Whitney Road, was granted a standard cultivation licence by Health Canada on July 24th 2020, on a legal understanding that we would not release products under our brand of Whistler Therapeutics, as it “construed” an actual therapeutic product and till there is clinical evidence, we would not be able to release products under brand Whistler Therapeutics. We pivoted and started our brand of EarthWolf Farms. EarthWolf farms was previously a certified organic hops farm, and Whistler Therapeutics has maintained that certification for growing outdoor cannabis on this property. We are using multiple regenerative and organic cultivation practices to help improve the health of our soil, water and air. Our first cultivation cycle was the summer of 2020, with inventory from the harvest stored over the winter of 2021 and processed slowly at a partners’ facility in the tri-cities area.

In early 2020, we managed to get a lease with a neighbouring property to our farm for a building which we plan on licensing for processing. We currently hold research and analytical licenses at this 10,600 square foot laboratory, initially built by a former mayor of Lillooet who also was a professor at the University of British Columbia.

We plan to operate year-round, with additional processing and preparation work to keep our core farm staff gainfully employed all year. In addition to our staff, we purchase goods and services from local businesses, contributing to the Lillooet economy. On this farm, we are selecting and breeding cannabis varieties that grow well in the local climate, which we will distribute to any local farmers.

Our current farms and processing centre (soon to be licensed) are the start of what we hope will become a thriving economy of local, independent businesses. With the support of the local government, we can help transition current black-market producers into the legal system, while creating new employment for many others.

We are dedicated to creating long-term high-quality jobs while protecting the health of our environment. We hope to bring a positive change to the local community and welcome feedback and communication from all. Anyone interested in obtaining a cannabis licence, learning more about the Cannabis Act and its subsequent Regulations is encouraged to call us or send an email. We welcome giving you tours to show you what an organic farm aspiring to become fully regenerative in 5 years’ time works and the many plants we grow alongside Cannabis Sativa.

Photo journey starting in April 2019 and ending in 2022 when this blog post is written.

April 19 2019 – Dogs (Louis & Mama Mae) roaming the hops field, looking towards the Fraser River.

April 20, 2019 – Burning cleared brush off, looking NE.

June 13th 2019 – Hops continue to grow.

July 7th 2019 – Daniel was shocked at the growth of the hops as the clouds lift up after a summer rain.

We harvested the hops and stored them as we would with cannabis in large refrigeration trucks.

Nov 6th 2019 – My co-founder and I arrived at our farm to find more trees had been taken down by our staff who were installing security cameras and poles, as they were in the way of the line of sight of cameras. We took the extra trees taken and made Hugel beds within the cultivation as a means of retaining water in the soil.

Nov 6th 2019 – Our fencing contractor left town so we had to finish the fencing ourselves as a team.

Feb 19th, 2020 – Over Dec 2019, Jan 2020 and Feb 2020, we installed two hoop house style greenhouses to start our plants. We had contractors install these in the coldest month of winter 2020.

Late June of 2020 – We wanted to test different techniques of retaining water, so we buried the ponderosa pine trees back in 2019 when we cleared some areas of the parcel and before licensing, we amended the soil with compost and organic fertilizers (Gaia green products). Underneath the Hugel beds are the ponderosa pine trees, then filled with dry tree branches, native Lillooet brush plants and any other plants that we took off the cultivation field during our preparations.

July 2020 – plants in greenhouses at the time of being brought into the site at the time of licensing from Health Canada. These plants are then taken outdoors, transplanted into the natural soil that has been amended with organic fertilizers and organic compost.

July 2020 – Planting commences post-licensing from Health Canada.

Late July 2020 after a week or so having plants outside in the terraced gardens zone of the field.

Late August or early Sept 2020 – our first cultivation cycle – Within no time, the plants vegetate and start flowering slowly.

Late July 2020 – After most of the planting is done and we are quite tired.

Sept 29, 2020 – We lined up our fence line with sunflowers to make our neighbours happy. We only learned the benefits of growing sunflowers in water retention in Jan 2022.

Sept 20, 2020 – A few months after licensing, we had to convince our new Lillooet community that we were intending to be around for a while, after initiatives by the community to change the zoning of our parcel (generator noise complaints escalated) and, local BC Hop turned hemp processor’s processing facility emitting odours towards Lillooet town proper.

Sept 2020- Plants before harvest as smoke from forest fires clear this summer morning.

Summer of 2020 – Mother nature confirms the health of our soil by giving us a variety of edible mushrooms.

Sept 2020 – Daniel harvesting tomatoes from the field for the Lillooet Friendship Society.

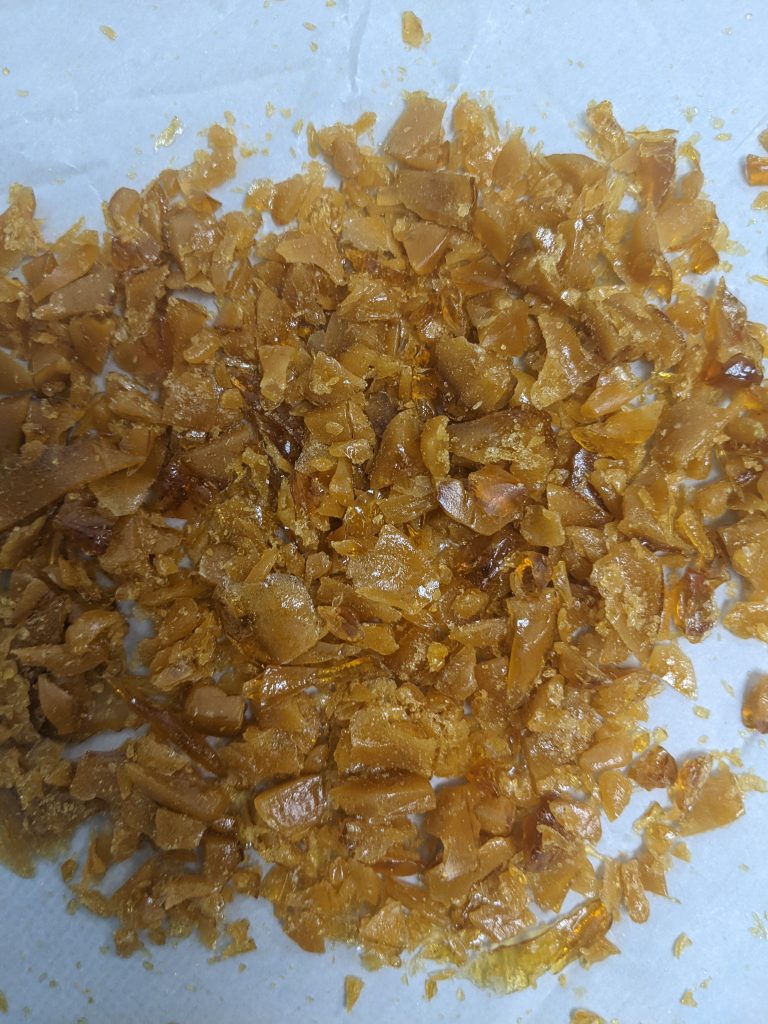

Oct 2020 – We tested the WT-300 (extraction equipment from Whistler Technologies) with the four cultivars of hops we were growing and it was a success.

Oct 19, 2020 – Hop Hash was successfully created through Whistler Technologies’ Ice water extraction equipment.

Oct 2020 – Hop hash storage in glass mason jars similar to how cannabis is stored. We categorized our inventory the same way we intended to do with our cannabis concentrates once processed.

Jan 2021 – After our first harvest and winter clean up – Looking at Fountain Peak.

Summer 2021 – Flowers around the security building within the farm.

Summer 2021 – This zone was tilled the first year. Not tilled the second year with peas as cover crops.

June 2021 – Plants after a few weeks of being transplanted outside in a zone that was not tilled the first year and had cover crops in the spring of 2021.

June 2021 – Forest fire smoke over Lillooet with plants on a sloped zone before the terrace gardens.

Summer 2021 – Food garden by the farmhouse that supplied staff lunches throughout the planting and harvest season.

Sept 2021 – Second-year plants almost ready for harvest.

Oct 2021 – Our high CBG Live Rosin which has a shatter like consistency.

Dec 2021 – Our first few concentrate edible cannabis oils are being produced at our partner’s processing facility by us for sale.

2023-01-26

Over a full year has gone by since I last updated this blog. It seems like yesterday we started EarthWolf Farms. It has been unbelievably busy and challenging operating in this nascent industry growing a business while we grow ourselves, as individuals, as teams and as a country.

Jan 2022 – Our edible cannabis oils were released into the Canadian recreational and medical markets via distributors (both provincial and private) by July 2022. We released our BC Rockstar edible cannabis oil first followed by our Kush blend; Zen Oil, both at concentrations of 25mg/ml to 30 mg/ml with total terpene concentrations of 2-5 mg/ml. These oils were received well having received many reviews from users who were able to recognize the oil formulation to be simple yet of quality ingredients. Earthwolf’s’ edible cannabis oils are made from three simple ingredients: bubble hash, organic coconut oil and organic olive oil. BC Rockstar was sold via Abba Medix to mainly veterans and patients who are registered with them and their associated clinics.

April 2022 – BC Rockstar Oil, a small batch, beyond full spectrum edible cannabis oil made from organic bubble hash, organic cold pressed coconut oil and organic cold pressed extra virgin olive oil, first released to veterans in Canada via Abba Medix.

February 2022 – At this stage of our operations, we had finished processing the biomass from 2020 into ice water hash/bubble hash and were going to start processing cultivars that were grown in 2021 summer grow season. We had harvested approximately 4000 kg of cannabis flower (wet weight) and it would take us a few months to go through processing all of this biomass into hash. We had started sales, so it was also time to start working on marketing efforts along with ramping up processing to replenish inventories to continue to support sales.

We continued to increase our inventory with driving the cannabis biomass from Lillooet to Port Coquitlam (Poco), where it was being processed by our staff and then packaged into final products for sale. A few of us were on the road quite often, especially our processing manager and Brishna, who drove from Lillooet to Poco multiple times a week and back.

Our team went through a transition in early 2022 with multiple roles remaining unfilled, resulting in additional responsibilities for Daniel and I (Brishna). We worked more than ever beginning of 2022 on our business and farm, staying up multiple late nights to work on operational tasks that normal business executives usually delegate, but we could not do so, either to current employees lacking the right skills or just not having the position filled due to budgetary constraints. We knew by March 2022, we would have to bring on additional help especially at our farm, so we started a search for who would become our master grower with Brishna meeting various growers from different parts of BC to see if they fit in with our company culture and shared core values of transparency, diligence, and sustainability.

March 2022 – Seedlings started to either become mother plants or production plants for the outdoor cultivation field.

By mid-March, we had brought on a full time Master Grower who would oversee our cultivation at our farm, and a Quality Control who would assist the Master Grower with batch records and trackability of plant operations. We were confident, of course, with hesitations still, that our new Master Grower would be able to handle the grow of a few thousand plants to give us approximately 5000-7000 kg of fresh cannabis flowers to add to inventory to become beautiful solventless concentrate products. Our new master grower had grown organically indoors before and outdoors for many years so once organic certification grow plan were submitted, we delegated as much as we could, and focused on sales and marketing efforts.

April 2022 – Field preparations are underway awaiting plants currently being housed in the hoop houses, started either from seed or clones of mother plants kept over the winter month from the season before.

April 2022 – Plants in the pots in hoop houses awaiting their transplant to the outdoor field.

By May 2022, we had three products selling in BC, so Daniel and I went on a sales trip to Vancouver Island visiting shops from Nanaimo all the way to Sooke, BC in our work vehicle, a Toyota Rav 4 sleeping along the way at parks or FSRs in a tent, to save on hotel or Airbnb costs that we would otherwise pay a staff member for. At this stage, we felt the industry’s downward spiral more, with less interest in our projects from investors while challenges in finding responsible and accountable employees continued to increase.

May 2022 – Vancouver Island Trip promoting our 3 selling products in BC. Above is Tundra Live Rosin.

The rest of spring 2022 we focused on getting clones cut at the farm, more cannabis flower biomass processed and out the door through our sale’s partner’s federal sales license (something which we still did not have at this time point in our development). There was still quite a bit of travel in that Brishna got hit once in March by our neighbor in our parking lot so there began car troubles for the next few months. After this incident, while driving through the Duffey, Brishna’s car got hit by random flying rocks off the mountain during the spring mountain thaw. Luckily, it was only the car that got hit as it was the driver passenger side that got hit having lost a window and a door panel not affecting the driver or the front of the car, although what a shock and event to witness! 3 days later, there was a major rock fall injuring multiple people with multiple deaths so again luckily, a lost door and window is nothing compared to a life.

Spring 2022 – Processing Lab Technician Pamela West scooping up bubble hash for our Fire Pack hash trio sampler product.